Proper

Sealing of Outdoor Coax Connectors [or Waveguide Splice]

Everyone

seems to have a different idea how to properly seal outdoor coax

connectors, such as where the antenna cable connects to the rigid Heliax

feedline, or short jumper cable. The fact is over time, most cables actually allow small

amounts of air and moisture to pass through the jacket and find its

way inside your connectors. This moist air is not a problem until a

rapid temperature shift occurs and condensation forms inside a

connector, typically every evening. Since most commercial installations use type-N connectors,

it takes only 1 drop to alter the SWR and began to reduce the overall

antenna performance. For example, even with just 1 layer of a good

moisture-proof vinyl tape such as Scotch 33, over a connector on a

VHF antenna, within a year there will be at least 3 drops of water

inside the connector. This will reduce the antenna performance by at

least 65% and usually much worse. Therefore, the objective is twofold - seal the connector

from weather and provide thermal resistance to prevent condensation

for occurring inside the connector. Below are several well proven ways to provide excellent

protection from the problem above.

Packing

with silicon gel or grease - This concept we learned from the Air Force. It

seems that whenever an airplane takes off & reaches altitude, and then

eventually lands, the temperature of some of the electrical &

electronics equipment [outside the passenger area] can vary more than 50

degrees F, and sometimes over 100 degrees. This thermal shock with moist outside air cause small amounts of

condensation in electrical connectors, which leads to erratic performance of fire control RADAR

and other Radio equipment. It had long been standard practice to fill

the AN style electrical connectors with silicone grease, to prevent

arcing between pins from moisture. So it also became a standard practice to pack the inside of all

type-N coax connectors with silicone gel. It has been my experience

this works very well, but is very messy to work with, in particular

at the top of a tower. Andrew

has long supplied a tiny unmarked tube of this with each Heliax

connector to weatherproof the inside of the front and rear of each

connector. If the silicon grease gets on the outside of

the cable or connectors, due to mis-handling, vinyl tape will not stick.

However, if you are assembling things on the ground, and you have

clean rags and solvent to cleanup with, go for it. This product is sold as Dow Corning 4 Electrical Insulating Compound and is widely available from $12 to $18 per 5.3 Oz. tube. I buy from Skygeek.com

for under $15 per tube. One tube will last for many years if used just

for coax connectors. You may also find new military surplus tubes that

are out-of-date, but will work just fine. Be sure to wrap the outside of

the connectors with at least two layers of Scotch 33 [and 2242] tape when complete. Be advised, this is not

the same product as silicon sealant, this is a gel that remains a gel

and does not become solid. Do not use silicone sealant inside a

connector.

Packing

with silicon gel or grease - This concept we learned from the Air Force. It

seems that whenever an airplane takes off & reaches altitude, and then

eventually lands, the temperature of some of the electrical &

electronics equipment [outside the passenger area] can vary more than 50

degrees F, and sometimes over 100 degrees. This thermal shock with moist outside air cause small amounts of

condensation in electrical connectors, which leads to erratic performance of fire control RADAR

and other Radio equipment. It had long been standard practice to fill

the AN style electrical connectors with silicone grease, to prevent

arcing between pins from moisture. So it also became a standard practice to pack the inside of all

type-N coax connectors with silicone gel. It has been my experience

this works very well, but is very messy to work with, in particular

at the top of a tower. Andrew

has long supplied a tiny unmarked tube of this with each Heliax

connector to weatherproof the inside of the front and rear of each

connector. If the silicon grease gets on the outside of

the cable or connectors, due to mis-handling, vinyl tape will not stick.

However, if you are assembling things on the ground, and you have

clean rags and solvent to cleanup with, go for it. This product is sold as Dow Corning 4 Electrical Insulating Compound and is widely available from $12 to $18 per 5.3 Oz. tube. I buy from Skygeek.com

for under $15 per tube. One tube will last for many years if used just

for coax connectors. You may also find new military surplus tubes that

are out-of-date, but will work just fine. Be sure to wrap the outside of

the connectors with at least two layers of Scotch 33 [and 2242] tape when complete. Be advised, this is not

the same product as silicon sealant, this is a gel that remains a gel

and does not become solid. Do not use silicone sealant inside a

connector.

Glue

filled heat-shrink tubing

- This concept came from the cable TV

industry. These guys also use silicon grease in some aspects of their

network, but to get a water-tight seal in underground connectors,

they use a heat-shrink tubing, with a heat-activated glue inside. it

is best to place a single wrap of vinyl tape over the connectors

before placing the tubing in place, otherwise you will have a sticky

glue mess on the connectors. Then proceed to heat the tubing with

a propane torch, evenly all around. The

tubing should extend beyond the connectors at least 2 inches, so

there is a cable jacket to cable jacket bond. To remove, simply cut the

plastic end to end and peel. This product works great, but

using a propane torch at the top of a tower is sometimes a problem, and

it

sometimes drips hot glue on the workers below. Again, this is great on

the ground, but tricky

in the air. This product is widely available for around $10 per 1 inch

x 48 inch lengths. Be advised some glues may crystallize from sun &

weather, therefore radio manufacturers like Codan recommend placing a single wrap of self-amalgamating rubber tape over the tubing.

Glue

filled heat-shrink tubing

- This concept came from the cable TV

industry. These guys also use silicon grease in some aspects of their

network, but to get a water-tight seal in underground connectors,

they use a heat-shrink tubing, with a heat-activated glue inside. it

is best to place a single wrap of vinyl tape over the connectors

before placing the tubing in place, otherwise you will have a sticky

glue mess on the connectors. Then proceed to heat the tubing with

a propane torch, evenly all around. The

tubing should extend beyond the connectors at least 2 inches, so

there is a cable jacket to cable jacket bond. To remove, simply cut the

plastic end to end and peel. This product works great, but

using a propane torch at the top of a tower is sometimes a problem, and

it

sometimes drips hot glue on the workers below. Again, this is great on

the ground, but tricky

in the air. This product is widely available for around $10 per 1 inch

x 48 inch lengths. Be advised some glues may crystallize from sun &

weather, therefore radio manufacturers like Codan recommend placing a single wrap of self-amalgamating rubber tape over the tubing.

Wrap

with real rubber tape - This is my preference when working on top of a tower,

or otherwise. It is the cleanest to use and does not rely on torches

or solvents to do a clean job. Scotch 130C can be used in place of

Scotch 2242, but is more

expensive. The price ranges from $6 to $12 per roll of 3/4 inch x 15

ft. The tape is 0.030 [1/32] inches thick and easily stretches, but do

not over stretch it. It is self-amalgamating, so it cannot be unpeeled

after a few days. Do not

apply the rubber tape directly to the connectors, as it bonds to itself

and will not peel off after a few days. To remove, it must be cut off

and will leave a black sticky mess on the connectors unless a single

wrap of vinyl tape is used first.

Wrap

with real rubber tape - This is my preference when working on top of a tower,

or otherwise. It is the cleanest to use and does not rely on torches

or solvents to do a clean job. Scotch 130C can be used in place of

Scotch 2242, but is more

expensive. The price ranges from $6 to $12 per roll of 3/4 inch x 15

ft. The tape is 0.030 [1/32] inches thick and easily stretches, but do

not over stretch it. It is self-amalgamating, so it cannot be unpeeled

after a few days. Do not

apply the rubber tape directly to the connectors, as it bonds to itself

and will not peel off after a few days. To remove, it must be cut off

and will leave a black sticky mess on the connectors unless a single

wrap of vinyl tape is used first.

Be sure to stretch the tape as you

apply it. Fresh tape [within a year] works better than old tape.

-

layer 1 is a thin vinyl tape which should be 15% overwrap and is to

protect the finish of the connectors, use Scotch 33 ;

-

layer 1 is a thin vinyl tape which should be 15% overwrap and is to

protect the finish of the connectors, use Scotch 33 ;

-

layer 2 is a thick natural rubber tape which should be 15%

over wrapped, and extended one inch, on both ends, beyond the prior

wrap, use Scotch 2242

-

layer 3 is a thick natural rubber tape which should be 15%

over wrapped, and extended one inch, on both ends, beyond the prior

wrap, use Scotch 2242

-

optional layer 4 is a thick natural rubber tape which should be 15%

over wrapped, and extended one inch, on both ends, beyond the prior

wrap, use Scotch 2242

-

Final layer 5 is a thin vinyl tape which should be 15% overwrap and is to

protect the prior natural rubber finish, use Scotch 33

When

you are done, you will probably have used a full roll of Scotch 2242

rubber tape. These 5 layers can be easily removed with a pen knife,

slicing length wise, and peeling off. Without layer 1, you will have

a tough time ending up with clean set of connectors as the self-amalgamating rubber

tape will leave a sticky and gooey finish.

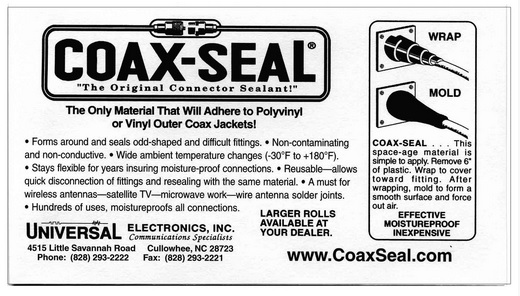

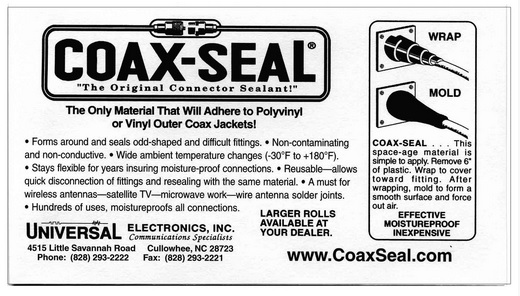

CoaxSeal.com makes

a fine reusable product that remains soft and pliable. It is easily

removed

and rarely leaves any residue. However, if the splice can be stepped on

or is in a traffic or climbing area, the sealant can be disturbed

or scrapped off, thereby exposing the connector to weather. I would

suggest placing a wrap of Scotch 33 vinyl tape over the CoaxSeal, for

protection from scrapes or dislodging. A typical roll is 1/2 inch

wide and 60" [5 ft]

long. A roll costs around $6 and is widely available at master distributors or on the Internet. Coax-Seal is

easily wrapped and then molded by hand to your desired finish.

CoaxSeal.com makes

a fine reusable product that remains soft and pliable. It is easily

removed

and rarely leaves any residue. However, if the splice can be stepped on

or is in a traffic or climbing area, the sealant can be disturbed

or scrapped off, thereby exposing the connector to weather. I would

suggest placing a wrap of Scotch 33 vinyl tape over the CoaxSeal, for

protection from scrapes or dislodging. A typical roll is 1/2 inch

wide and 60" [5 ft]

long. A roll costs around $6 and is widely available at master distributors or on the Internet. Coax-Seal is

easily wrapped and then molded by hand to your desired finish.

There

may be other practical methods to moisture proof and thermally insulate

the connectors, but these above are the best we have seen. For example,

there are snap-on covers that provide thermal protection, but are not

always waterproof, even filled with silicone gel, as shown to the left.

[and what a mess when you open to perform service]

There

may be other practical methods to moisture proof and thermally insulate

the connectors, but these above are the best we have seen. For example,

there are snap-on covers that provide thermal protection, but are not

always waterproof, even filled with silicone gel, as shown to the left.

[and what a mess when you open to perform service]

As

with all products, some are better than others. It all depends upon on

how important it is doing the job right the first time, and

adopting a procedure for your crew, so even a not-so-bright employee,

cannot do it wrong.

Revised May 19, 2018 by Fred Daniel

Packing

with silicon gel or grease - This concept we learned from the Air Force. It

seems that whenever an airplane takes off & reaches altitude, and then

eventually lands, the temperature of some of the electrical &

electronics equipment [outside the passenger area] can vary more than 50

degrees F, and sometimes over 100 degrees. This thermal shock with moist outside air cause small amounts of

condensation in electrical connectors, which leads to erratic performance of fire control RADAR

and other Radio equipment. It had long been standard practice to fill

the AN style electrical connectors with silicone grease, to prevent

arcing between pins from moisture. So it also became a standard practice to pack the inside of all

type-N coax connectors with silicone gel. It has been my experience

this works very well, but is very messy to work with, in particular

at the top of a tower. Andrew

has long supplied a tiny unmarked tube of this with each Heliax

connector to weatherproof the inside of the front and rear of each

connector. If the silicon grease gets on the outside of

the cable or connectors, due to mis-handling, vinyl tape will not stick.

However, if you are assembling things on the ground, and you have

clean rags and solvent to cleanup with, go for it. This product is sold as Dow Corning 4 Electrical Insulating Compound and is widely available from $12 to $18 per 5.3 Oz. tube. I buy from Skygeek.com

for under $15 per tube. One tube will last for many years if used just

for coax connectors. You may also find new military surplus tubes that

are out-of-date, but will work just fine. Be sure to wrap the outside of

the connectors with at least two layers of Scotch 33 [and 2242] tape when complete. Be advised, this is not

the same product as silicon sealant, this is a gel that remains a gel

and does not become solid. Do not use silicone sealant inside a

connector.

Packing

with silicon gel or grease - This concept we learned from the Air Force. It

seems that whenever an airplane takes off & reaches altitude, and then

eventually lands, the temperature of some of the electrical &

electronics equipment [outside the passenger area] can vary more than 50

degrees F, and sometimes over 100 degrees. This thermal shock with moist outside air cause small amounts of

condensation in electrical connectors, which leads to erratic performance of fire control RADAR

and other Radio equipment. It had long been standard practice to fill

the AN style electrical connectors with silicone grease, to prevent

arcing between pins from moisture. So it also became a standard practice to pack the inside of all

type-N coax connectors with silicone gel. It has been my experience

this works very well, but is very messy to work with, in particular

at the top of a tower. Andrew

has long supplied a tiny unmarked tube of this with each Heliax

connector to weatherproof the inside of the front and rear of each

connector. If the silicon grease gets on the outside of

the cable or connectors, due to mis-handling, vinyl tape will not stick.

However, if you are assembling things on the ground, and you have

clean rags and solvent to cleanup with, go for it. This product is sold as Dow Corning 4 Electrical Insulating Compound and is widely available from $12 to $18 per 5.3 Oz. tube. I buy from Skygeek.com

for under $15 per tube. One tube will last for many years if used just

for coax connectors. You may also find new military surplus tubes that

are out-of-date, but will work just fine. Be sure to wrap the outside of

the connectors with at least two layers of Scotch 33 [and 2242] tape when complete. Be advised, this is not

the same product as silicon sealant, this is a gel that remains a gel

and does not become solid. Do not use silicone sealant inside a

connector.

Glue

filled heat-shrink tubing

Glue

filled heat-shrink tubing Wrap

with real rubber tape

Wrap

with real rubber tape  -

layer 1 is a thin vinyl tape which should be 15% overwrap and is to

protect the finish of the connectors, use

-

layer 1 is a thin vinyl tape which should be 15% overwrap and is to

protect the finish of the connectors, use

There

may be other practical methods to moisture proof and thermally insulate

the connectors, but these above are the best we have seen. For example,

there are snap-on covers that provide thermal protection, but are not

always waterproof, even filled with silicone gel, as shown to the left.

[and what a mess when you open to perform service]

There

may be other practical methods to moisture proof and thermally insulate

the connectors, but these above are the best we have seen. For example,

there are snap-on covers that provide thermal protection, but are not

always waterproof, even filled with silicone gel, as shown to the left.

[and what a mess when you open to perform service]